Rubber Bridge Expansion Joints

Understanding Rubber Bridge Expansion Joints

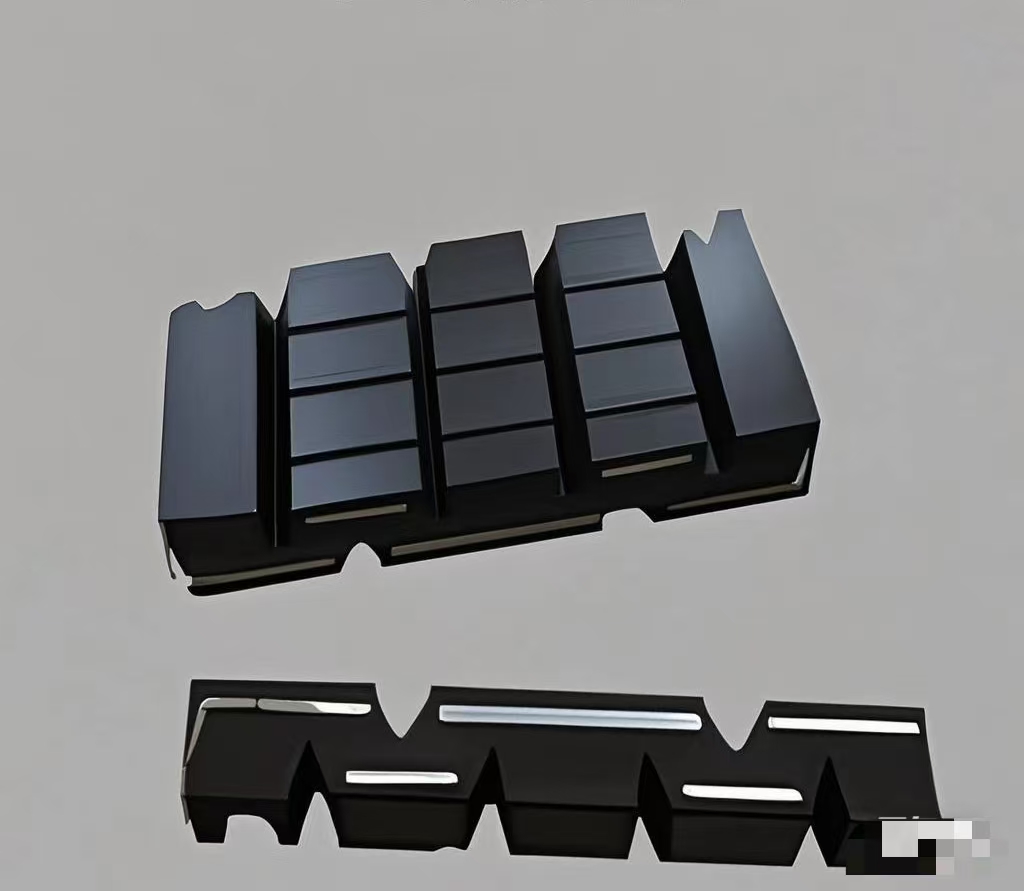

The expansion body in the plate-type rubber expansion joint is a structure made of rubber, steel plate or angle steel. It is designed and manufactured based on the principle of low shear modulus of rubber material. The shear-type rubber expansion body is provided with upper and lower grooves. The load-bearing steel plate and anchoring steel plate are buried in the rubber body, and there are reserved bolt holes, which are connected to the beam end as a whole through bolts. Generally, rubber belt is used as the span material. It is suitable for ordinary highway bridge projects with expansion amount ≤60mm.

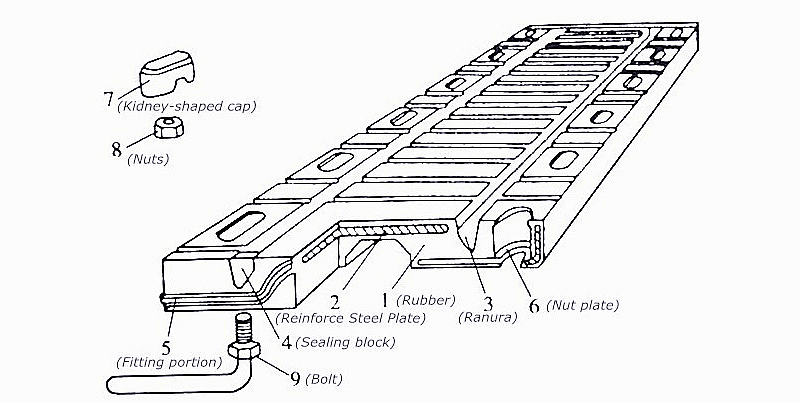

The structure of rubber expansion joints:

Rubber bridge expansion joints are composed of rubber, reinforcing steel plates, gaskets, sealing blocks, matching parts, nut plates, waist-shaped caps, nuts, bolts, etc.

Performance indicators:

Adaptable temperature: -40℃ to 60℃

Hardness: 60±5

Features:

1. Simple structure and convenient installation

2. Good waterproofness

3. Strong elasticity

4. Good durability

During installation, the bolt holes at the bottom and each connection are filled with adhesive to make the entire rubber bridge expansion joint highly waterproof.

Rubber bridge expansion joints ensure smooth and noiseless operation of vehicles.

Application:

1. Applicable scenarios: small and medium span bridges (≤80mm), urban viaducts, building settlement joints, parking lots, etc.

2. Limitations: Modular or finger-type expansion joints need to be selected when the deformation is large (>200mm).

Regular inspection is required under long-term heavy-load traffic.